EXPERIENCE

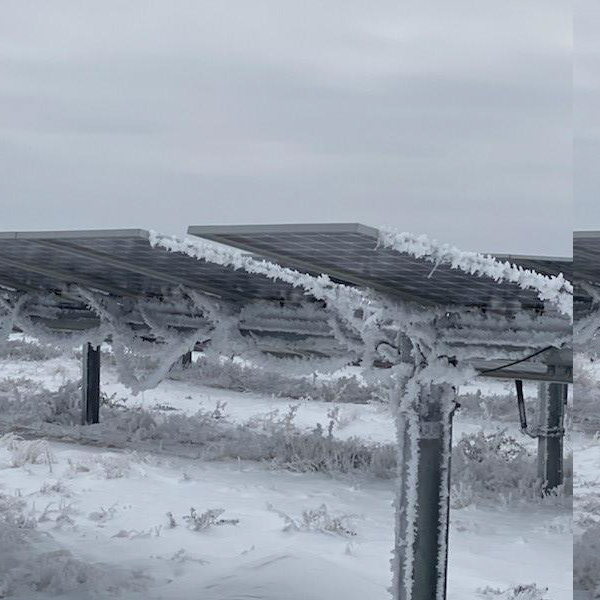

The large-scale of utility solar projects can be daunting, especially with the volume of testing and certification requirements for commissioning. Thorough acceptance testing is critical to certify equipment reliability and SCADA functionality before the site's commercial operation date. These checks include equipment verifications, burn-in testing, control programs, and feedback signal loops throughout the array and substation.

However, even with rigorous quality assurance processes in place, faults can still pass unnoticed, particularly in large fields leaving developing operational technicians to be the catch-all. Component infant mortality is inevitable on projects of this scale and resolving punch-list mitigation issues can be time-consuming as well as frustrating for owners, commissioning teams, and construction affiliates. In many cases, substantial man-hours are lost as teams are forced to review contracts for "flexibility".

The result of all this complexity is that issues can slip through the cracks, leading to potentially significant oversights.

QUALITY

SME leverages the energy industry's best commissioning practices while also having boots-on-ground experience through turnover on some of the world's largest solar, geothermal, and data center projects. For solar projects specifically, developed methods of procedure have enabled hard-working field teams to safely and effectively re-commission over 2 million solar panels, 200 inverter skids, 3000 combiner & load break disconnects as well as a few 345kV substations.

We understand that commissioning any energy project is a complex and time-consuming process, and we don't believe in cutting corners. Our processes prioritize quality and safety over speed, ensuring that every component is fully tested and certified before the project is operational.